kiwikr.co.nz

|

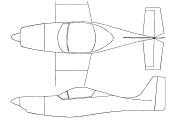

My Vertical Stabilser and rudder will utilise the NACA63009 profiles sourced from Mark Langfords web site.

These profiles differ from the standard KR2S profiles by being 2" higher at 45" and use a different airfoil cross section.

The increased height should improve the effectiveness of the rudder and using the NACA profile should also make the vertical stabiliser more

effective while reducing drag. | ||||||

Tuesday 13th October 2009. Given I had some time available I made a start on measuring up the positioning of the rudder post on the rear of

the upper longerons. The rudder post is part of the Vertical stabiliser so I have started a new page to detail the build of the Vertical

Stabiliser.

Tuesday 13th October 2009. Given I had some time available I made a start on measuring up the positioning of the rudder post on the rear of

the upper longerons. The rudder post is part of the Vertical stabiliser so I have started a new page to detail the build of the Vertical

Stabiliser.

| ||||||

|

Wednesday 14th October 2009. I initially needed to work out how much longer the top longerons will need be than the lower ones given the

angle of the tail post is 7 degrees. To do this I use the following trig calculation. Using a triangle with an adjacent side of 11 inches (the height of the fuselage at the tail) and a theta angle of 7 degress (the angle of the tail post from vertical) I need to find the length of the opposite side

Trigonometry says tan(theta) = Opposite / Adjacent

therefore tan(7) = Opp / 11

==> 0.123 = Opp / 11

==> Opp = 0.123 * 11

==> Opp = 1.35" or 1 7/20"

This tells me that given the total fuselage length of 145.5 inches as shown on the plans, I need to add 1.35" to the top longeron to allow

for the angle of the tail post. I had already worked out the angles manually and measured a figure of 1 11/32 which you can see in the photo.

This is equal to 1.34" which was pretty close to the 1.35" calculated above. | ||||||

After marking in the total length of 145.5" + 1.35" on the top longeron, I measured back 5/8" for the width of the tail post itself and then

6mm for the tail post doubler. This gave me the cutting line for the top of the upper longerons. I then drew in a 7 degree line from this line.

I checked and triple checked my figures before starting these cuts as there is no going back once I start. I used a hand coping saw as shown

in the photo to make the cuts.

After marking in the total length of 145.5" + 1.35" on the top longeron, I measured back 5/8" for the width of the tail post itself and then

6mm for the tail post doubler. This gave me the cutting line for the top of the upper longerons. I then drew in a 7 degree line from this line.

I checked and triple checked my figures before starting these cuts as there is no going back once I start. I used a hand coping saw as shown

in the photo to make the cuts.

| ||||||

And this is the result. I still need to clean up the ends of the longerons to remove the cut marks but will wait to do this once I have

the cut out the doubler to use as a guide.

And this is the result. I still need to clean up the ends of the longerons to remove the cut marks but will wait to do this once I have

the cut out the doubler to use as a guide.

| ||||||

After cutting the top longerons I then made up the 6mm doubler for the rudder post. I checked the plans and then confirmed my calculations

for the height and width of the doubler with those on Darren Cromptons site. The doubler is 18" in height and is 1.625" (1 5/8") wide for

the bottom 12", narrowing to 1.52" inches at the point where the rudder template meets the doubler (5" above the top longeron).

The forward face of the doubler is offset from the rear of the fuselage by 22mm. (5/8" (approx 14mm) + 6mm = 22mm) so this needed to be

allowed for when drawing in the lines where the longerons meet the doubler. Also the sides of the doubler are cut at an angle of 2.54 degrees

to match the sides of the rudder post itself. The picture shows the doubler with the lines where it engages the longerons drawn in.

After cutting the top longerons I then made up the 6mm doubler for the rudder post. I checked the plans and then confirmed my calculations

for the height and width of the doubler with those on Darren Cromptons site. The doubler is 18" in height and is 1.625" (1 5/8") wide for

the bottom 12", narrowing to 1.52" inches at the point where the rudder template meets the doubler (5" above the top longeron).

The forward face of the doubler is offset from the rear of the fuselage by 22mm. (5/8" (approx 14mm) + 6mm = 22mm) so this needed to be

allowed for when drawing in the lines where the longerons meet the doubler. Also the sides of the doubler are cut at an angle of 2.54 degrees

to match the sides of the rudder post itself. The picture shows the doubler with the lines where it engages the longerons drawn in.

| ||||||

Thursday October 15 2009. Tonight I drew up a diagram to show all the various angles and so I could work out the height for a temporary spacer

to sit between the upper and lower longerons. This will give me the the correct distance between the longerons.

Thursday October 15 2009. Tonight I drew up a diagram to show all the various angles and so I could work out the height for a temporary spacer

to sit between the upper and lower longerons. This will give me the the correct distance between the longerons.

| ||||||

This is the spacer fitted between the longerons.

This is the spacer fitted between the longerons.

| ||||||

Sunday October 18 2009. With the temporary spacer fitted, I placed the doubler against the existing top longeron cut to check the angle

and to make sure the doubler engages the bottom longeron at the line I have calculated it should intercept to give a 7 degree angle.

It was pretty close but still required a little sanding to get the angle correct. This gave me an opportunity to clean up the cutting

lines on the top longerons.

Sunday October 18 2009. With the temporary spacer fitted, I placed the doubler against the existing top longeron cut to check the angle

and to make sure the doubler engages the bottom longeron at the line I have calculated it should intercept to give a 7 degree angle.

It was pretty close but still required a little sanding to get the angle correct. This gave me an opportunity to clean up the cutting

lines on the top longerons.

| ||||||

With the top angle sorted I then clamped the lower longeron firmly and used a laser to check the alignment of the top and bottom set of longerons.

You can see the laser line on the forward face of the spacer block between the two longerons. This task required the assistance of my wife as

you need at least two sets of hands to secure everything in place while the clamps are tightened.

With the top angle sorted I then clamped the lower longeron firmly and used a laser to check the alignment of the top and bottom set of longerons.

You can see the laser line on the forward face of the spacer block between the two longerons. This task required the assistance of my wife as

you need at least two sets of hands to secure everything in place while the clamps are tightened.

| ||||||

With everything checked, I then cut the lower longerons using my hand coping saw.

With everything checked, I then cut the lower longerons using my hand coping saw.

| ||||||

Once I had cleaned up the ends of the lower longerons with a file and coarse sand paper I then set up the doubler for glueing. I used the laser

to again ensure the doubler was aligned vertically and centered. Once I was satisfied I had everything aligned, I drilled

four 1.6mm holes through the doubler and into each longeron to use as guides for panel pins when glueing.

Once I had cleaned up the ends of the lower longerons with a file and coarse sand paper I then set up the doubler for glueing. I used the laser

to again ensure the doubler was aligned vertically and centered. Once I was satisfied I had everything aligned, I drilled

four 1.6mm holes through the doubler and into each longeron to use as guides for panel pins when glueing.

| ||||||

With the glue applied I lightly hammered the four small panel pins into the guide holes to ensure everything was aligned. You can just see the

head of the pins in the photo at right.

With the glue applied I lightly hammered the four small panel pins into the guide holes to ensure everything was aligned. You can just see the

head of the pins in the photo at right.

| ||||||

Once I had everything set up I checked the angle of between the top longeron and the doubler and found it to be slightly less than 7 degrees

for some reason. It took me a bit to figure out that the weight of the clamps was bending the longerons down sufficiently to reduce the angle.

I quickly cut a support to lift the top longerons back up to straight and level and the angle between the longerons and the doubler came back

to 7 degrees. You can see the support in the photo at right and the builders bevel set at 7 degrees on top of the longeron up against the doubler.

Once I had everything set up I checked the angle of between the top longeron and the doubler and found it to be slightly less than 7 degrees

for some reason. It took me a bit to figure out that the weight of the clamps was bending the longerons down sufficiently to reduce the angle.

I quickly cut a support to lift the top longerons back up to straight and level and the angle between the longerons and the doubler came back

to 7 degrees. You can see the support in the photo at right and the builders bevel set at 7 degrees on top of the longeron up against the doubler.

| ||||||

25th - 26th Apr 2011. It has been a while since I did any work on the VS but this evening I made a start on it again. Initially I have decided to draw up

a full size plan of the VS so for the last couple of evenings I have been drawing this on a sheet of paper on my work bench. The photos show the KR plans

as provided and the plans I have drawn with respect to the dimensions of my fuselage boat and utilising Mark Langfords NACA VS profiles.

25th - 26th Apr 2011. It has been a while since I did any work on the VS but this evening I made a start on it again. Initially I have decided to draw up

a full size plan of the VS so for the last couple of evenings I have been drawing this on a sheet of paper on my work bench. The photos show the KR plans

as provided and the plans I have drawn with respect to the dimensions of my fuselage boat and utilising Mark Langfords NACA VS profiles.

| ||||||

30 Apr 2011. This evening I cut the three spar blanks for the front, middle and rear spars of the VS and then made a start cutting and shaping the middle

spar which forms the stern post of the kR

30 Apr 2011. This evening I cut the three spar blanks for the front, middle and rear spars of the VS and then made a start cutting and shaping the middle

spar which forms the stern post of the kR

| ||||||

After trimming it to fit to the existing ply doubler this how it looks with the hinges laid on to check for fit. The method I use to make the

spars was much the same as that used for the HS spars in that I cut the spar blank down to the widest width using the thicknesser then swapped to using

an electric hand planer to remove the gross amounts of timber to within 1-2mm of the final shape and then finally finished the shape with a hand plane

and files. Its a bit tedious but if you take your time the results look good.

After trimming it to fit to the existing ply doubler this how it looks with the hinges laid on to check for fit. The method I use to make the

spars was much the same as that used for the HS spars in that I cut the spar blank down to the widest width using the thicknesser then swapped to using

an electric hand planer to remove the gross amounts of timber to within 1-2mm of the final shape and then finally finished the shape with a hand plane

and files. Its a bit tedious but if you take your time the results look good.

| ||||||

With the stern post complete I glued it into place at the same time as I did glued in the 'N' position fuselage members to support the front spar of the

HS. I used a laser to check its vertical alignment.

With the stern post complete I glued it into place at the same time as I did glued in the 'N' position fuselage members to support the front spar of the

HS. I used a laser to check its vertical alignment.

| ||||||

Next I moved cut out the templates for the VS using Mark Langfords NACA profiles. I glued the profiles onto 2.5mm ply and cut them out using my scroll

saw. Unfortunately the photo is not too good so it is not that clear.

Next I moved cut out the templates for the VS using Mark Langfords NACA profiles. I glued the profiles onto 2.5mm ply and cut them out using my scroll

saw. Unfortunately the photo is not too good so it is not that clear.

| ||||||

After cutting out the templates I then slid the larger one over the stern post and to my annoyance I found that the stern post is not square on to the

firewall. The front of the template is squewed to port by about 3-4 degrees. I obviously did not cut the longerons off squarely when I originally

fit the ply doubler. As such I will need to remove the stern post and doubler and remake them. This photo shows the rear of the fuselage after

the stern post was removed. I used an electric jigsaw to remove the stern post and then an electric planer and heat gun plus chisel to remove the

last remnants of the glued ply from the ends of the longerons. I was then able to remeasure the longerons with reference to the HS support web and

re-cut them square to the firewall.

After cutting out the templates I then slid the larger one over the stern post and to my annoyance I found that the stern post is not square on to the

firewall. The front of the template is squewed to port by about 3-4 degrees. I obviously did not cut the longerons off squarely when I originally

fit the ply doubler. As such I will need to remove the stern post and doubler and remake them. This photo shows the rear of the fuselage after

the stern post was removed. I used an electric jigsaw to remove the stern post and then an electric planer and heat gun plus chisel to remove the

last remnants of the glued ply from the ends of the longerons. I was then able to remeasure the longerons with reference to the HS support web and

re-cut them square to the firewall.

| ||||||

June 2011. Moving on from the sternpost problem I have now decided to make the VS as a complete unit sitting on the bench, much the same as I did for the HS,

and then fit the complete unit to the rear of the aircraft. As such I have started to assemble all the components together on the bench. I will be making up

a jig to support the spars next. Note that I made three sets of spars before I was satisfied with the final results.

June 2011. Moving on from the sternpost problem I have now decided to make the VS as a complete unit sitting on the bench, much the same as I did for the HS,

and then fit the complete unit to the rear of the aircraft. As such I have started to assemble all the components together on the bench. I will be making up

a jig to support the spars next. Note that I made three sets of spars before I was satisfied with the final results.

| ||||||

July 5th-7th 2011. This is the jig I built for the vertical stabiliser. All I did was use VS rib templates cut in half and laid on the timber to cut

out matching notches for the spars and then screwed these to the bench. As can be seen from the photo I have fitted the hinges between the middle and

rear spars and aligned these with a steel rod.

July 5th-7th 2011. This is the jig I built for the vertical stabiliser. All I did was use VS rib templates cut in half and laid on the timber to cut

out matching notches for the spars and then screwed these to the bench. As can be seen from the photo I have fitted the hinges between the middle and

rear spars and aligned these with a steel rod.

| ||||||

This is a close up of the bottom jig. I have cut a small hole in my bench to allow the bottom hinge/bell crank to be fitted while the VS is in the jig.

This is a close up of the bottom jig. I have cut a small hole in my bench to allow the bottom hinge/bell crank to be fitted while the VS is in the jig.

| ||||||

Sept 11th 2011. I haven't done much on the KR over the winter. It has been a particularly cold winter this year with snow falling in Auckland for the

first time in 40 or 50 years. However I have finally got motivated and with the VS sitting in the jig I have now secure the spars with gussets.

These are the top gussets being glued into place.

Sept 11th 2011. I haven't done much on the KR over the winter. It has been a particularly cold winter this year with snow falling in Auckland for the

first time in 40 or 50 years. However I have finally got motivated and with the VS sitting in the jig I have now secure the spars with gussets.

These are the top gussets being glued into place.

| ||||||

I have made up the hinges the same as those for the VS using bronze bushings for bearings. While I was glueing the gussets I also glued the

hinges in place at the same time.

I have made up the hinges the same as those for the VS using bronze bushings for bearings. While I was glueing the gussets I also glued the

hinges in place at the same time.

| ||||||

With the glue dry and the VS removed from the jig the whole unit is quite rigid and can be carried around in one piece. It is now time to fit the VS

to the support webs in the rear of the fuselage. This is covered in the rear fuselage section.

With the glue dry and the VS removed from the jig the whole unit is quite rigid and can be carried around in one piece. It is now time to fit the VS

to the support webs in the rear of the fuselage. This is covered in the rear fuselage section.

| ||||||

www.kiwikr.co.nz