On Friday the 20th November 2009, my wife and I flew down to Christchurch for the weekend and on Saturday the 21st I drove

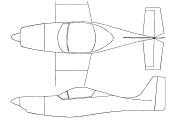

out to Sumner and caught up with Robin Macdonald. Robin is rebuilding a KR2 that had been registered with NZ CAA as ZK-KRJ

and which he purchased as a completed aircraft but that needed some repairs. Robin said once he started on the repairs,

the more he investigated the more things he found that needed to be replaced or repaired.

When I went to visit with Robin he had pretty much completed the replacement of the controls to use pushrods, he has built

a replacement turtle deck and has built a replacement canopy. He is in the process of building new aluminium fuel tanks

and new tail feathers for the aircraft as well.

The photo's below are the ones I took during the visit.

This is Robin and his KR in the workshop. It is quite a snug fit but there is still plenty of room to get round the aircraft. Robin said to me

that if he was building an aircraft from scratch he would leave the fitting of the horizontal stabiliser and stub wings to as late as possible

in the build while working to finish the fuselage that way you don't need to continually walk around these apendages.

Robin has replaced the previous cable controls with pushrods. This is his dual control column setup.

The elevator pushrod drives a bellcrank attached behind the rear spar.

The bellcrank behind the rear spar connects via two tensioned cables to another bellcrank at the rear of the fuselage to drive the elevator pushrod.

The aileron pushrods exit the fuselage just behind the front spar and connect to bellcranks mounted between two lengths of aircraft grade 1"

aluminium angle. These bellcranks connect to the ailerons bellcranks via another small pushrod which was not fitted when this photo was

taken.

Robin has fitted flaps to his KR which are mounted on a spruce hinge plate mounted behind the rear spar.

Because Robin wants to make the flaps hinges accessible and removable on his KR he has attached the hinges using anchor nuts. The anchor nuts

are riveted to a small piece of stainless steel (approx 1" x 0.5") and then the stainless steel is glued to the spruce hinge plate. Robin has used

this method of securing attachments in a number of places on his KR.

The flap actuator arm is driven via a torque tube that crosses behind the rear spar. The actuator arm has an elongated slot milled into it

to allow a sliding bolt to move as the flap is lowered and raised. Simple and efficient.

Robin is also replacing the tail feathers of his KR and has completed the build of the frame for the horizontal stabiliser.

This is his solution for the hinges for his horizontal stabiliser. Again simple and efficient. Note the use of anchor nuts to secure the hinge bolts.

Also note that Robin has his Rod End Bearings in double shear, unlike the Dr Dean approach which only has the REB in single shear.

Robin has also created a new turtle deck for the KR. He is unsure yet as to whether this will be the final shape for the turtle deck so

he has created a simple fibreglass fairing without foam backing to see how it looks. As he says, if he decides to change it he can readily

make up a new mould and create another one.

And tucked away in the roof of the garage next door to his shed is his completed canopy. If I recall correctly Robin said the original

canopy was cracked and he sourced the new one from another builder who sold Robin a complete set of Rand Robinson parts which included

a new canopy. He has spent a considerable period of time shaping and fitting the new canopy to the aircraft.